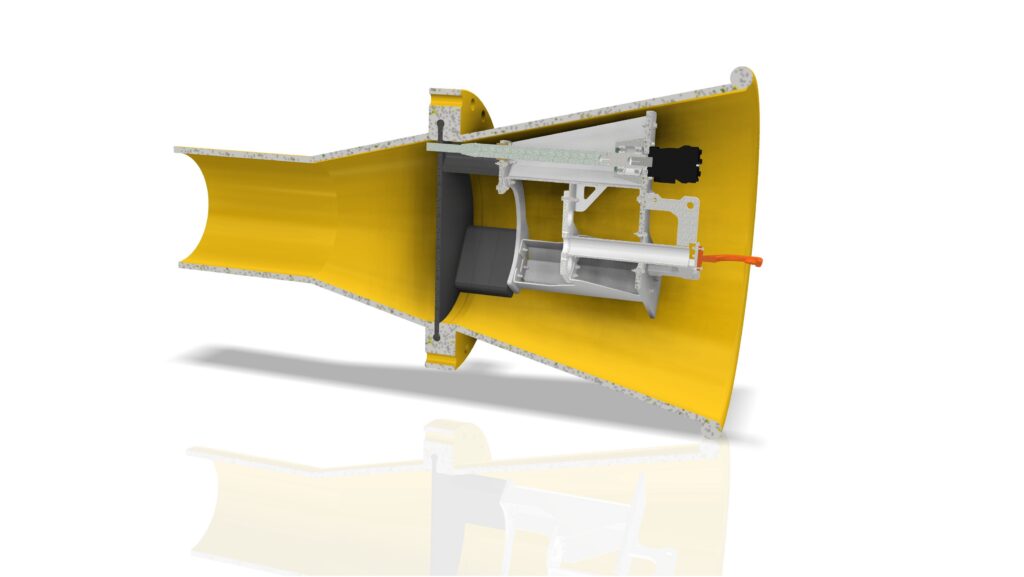

Each tool has a lightweight aluminium/POM frame and a drill head rotated by a hydraulic motor. The drill head itself spins to cut through the reinforced rubber diaphragm, while the ROV rotates the entire tool around the bellmouth to work its way around the full circumference. The design guides the cutter inside the bellmouth and mills out the rubber diaphragm without scarring the structure.

Design reviews were wrapped up in roughly a month, and manufacturing, FAT and shipping were completed within three weeks. The January offshore campaign removed every diaphragm within spec, and the feedback gathered is shaping the next generation of cutting tools.

Case summary

| Industry | Oil&Gas (IMR) – cutting and removal of reinforced rubber diaphragms from J-tubes prior to umbilical/riser installation. |

| Delivery | Three bespoke J-tube diaphragm cutting tools (Ø 462 mm long, Ø 318 mm long and a modified short variant) designed for ROV handling. |

| Customisation | Tools created to fit non-standard J-tube diameters. Low-weight aluminium/POM construction. The drill head is driven by a hydraulic motor, and the ROV manipulator rotates the entire tool around the diaphragm to perform the cut. Integrated guiding frame to protect bellmouth. |

| Duration/scope | ∼1 month design phase. Production/testing/shipping in 3 weeks. Offshore operations 19 days. |

| Location | Utsira region, North sea. |