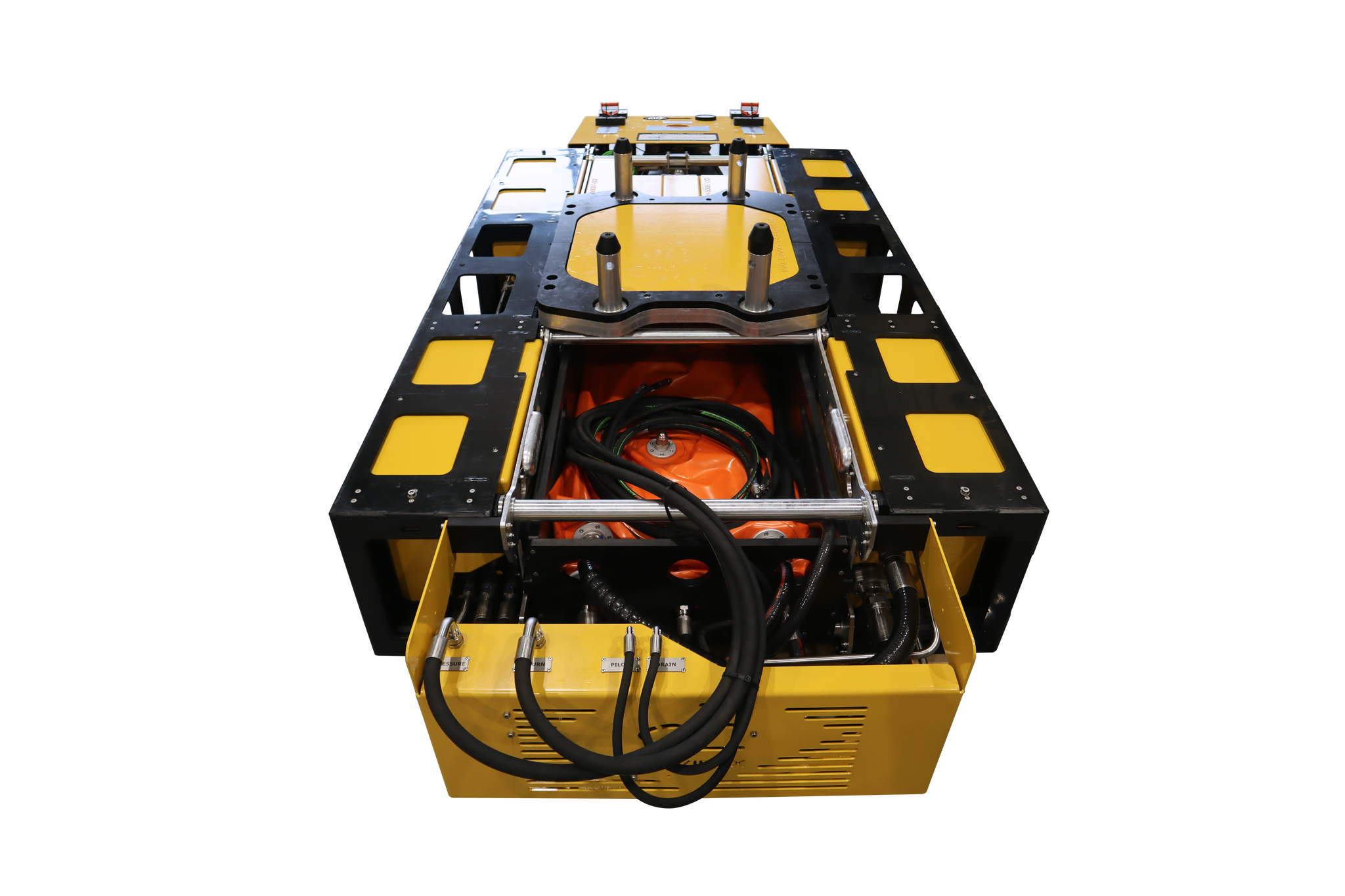

Octopoda GEN-2 BOP Shutdown Skid

Features

- High Flow / High Pressure

- Two stage pump

- API 53S compliance

- Max output pressure 345 Bar

- Max output flow 300 LPM

- Field proven pump technology

- Digital flowmeter and pressure

- Software with logging / chart

- RS232 24VDC Interface

- 325L Bladder reservoir

- Compact and low weight design

- Rated to 3,000 MSW

Typical Operations

- BOP emergency shut down

- Secondary BOP stack control

- Fluid injection & pressure testing

To meet a secondary intervention emergency and the API S53 standards, the BOP Shutdown Skid is designed and built to operate the BOP’s rams with a maximum pressure of 345 Bar and 300 LPM, using a field proven two stages pump technology.

The BOP Shutdown Skid is a 2 stage high pressure / high flow pump designed in conjunction with Dynaset. Utilizing two HPW90/150 pumps, two HPW460/50 pumps and a manifold frame to allow 345 Bar and 100 LPM simultaneously.

The system pressure is built up in two separate stages. The system is started by piloting supply valve which starts the 2 x LP pumps running at 300 LPM, when pressure builds up to 90 Bar the 2nd stage automatically starts the 2 x HP pumps which are pressurized up to a maximum of 345 Bar at a flow rate of 100 LPM.