A global EPC contractor needed to clear reinforced rubber diaphragms from a series of J‑tubes before installing new risers and an umbilical. The standard J‑tube diaphragm cutter wasn’t sized for...

Read MoreROV / DIVER Torque Multiplier GEN-2

Features

- Mechanical torque Tool

- Class 1 – 4 multiclass end effector

- No hydraulic power required (No leakage)

- No electric power & communication required

- Torque and Turns feedback display

- ROV adjustable clutch for safe valve operations

- Mechanical latch mechanism

- ROV and diver operable

- Environmental Friendly compensation fluid

Typical Operations

- Class 1-4 valve operations up to 1200 Nm

- Paddle valve operations

- MQC plate latch / de-latch

- ROV / Diver Intervention works

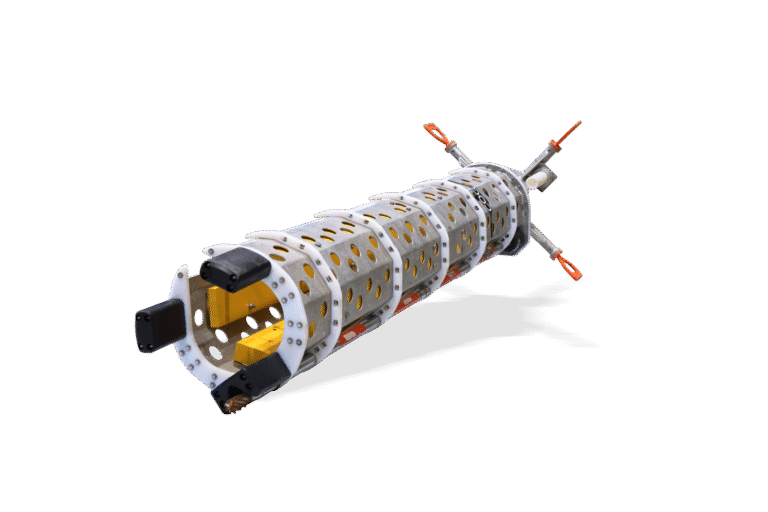

The Torque Multiplier Tool Gen-2 is a compact and ROV friendly multiclass torque tool designed for operating Class 1-4 subsea valves and MQC plates up to 1200 Nm torque applications.

The Torque Multiplier Tool (TMT) is a fully mechanical ROV manipulator/diver torque tool that require no hydraulic or electric power- and communication. Reducing the risk of hydraulic fluid spill, hose management and electrical cables. The tool comes with a mechanical latch system for standard API 17D bucket. Torque & Turns display is powered by batteries and is turned on/off or reset using flashing illumination. The Torque Setting System (calibration/operation) enables the operator to both adjust and verify torque output when subsea. The Torque Multiplier Tool has a built-in memory function that enables logging of valve operations when required. The logging files is transferred to laptop through USB adaptor cable. Other end effector available upon request (paddle valves)

Track record

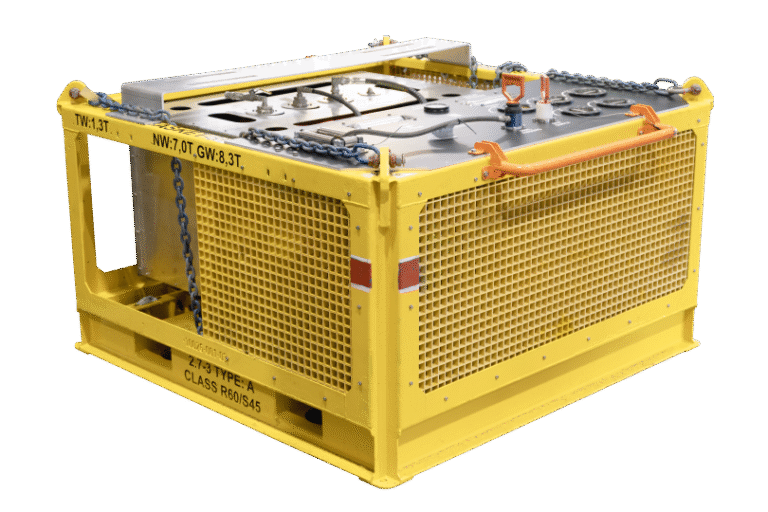

Reservoir basket with integrated hose reel for barrier-testing a multiphase flow meter

A North Sea operator who had previously completed a similar operation with Envirent in 2022, came back for a reliable pumping solution to flush and barrier‑test a multiphase flow meter. Envirent...

Read MoreIntegrated grease pump basket for subsea maintenance (IMR)

A subsea contractor needed to inject grease into rotating components during an IMR operation in the North Sea and returned to Envirent after a positive experience on a previous project. Envirent...

Read More