A global EPC contractor needed to clear reinforced rubber diaphragms from a series of J‑tubes before installing new risers and an umbilical. The standard J‑tube diaphragm cutter wasn’t sized for...

Read MoreTest Jig Class 1-4 Transducer System

Typical Operations

- Torque Tool Class 1-4 Operations

- Deck Testing

Features

- Stainless steel transducer with “SMART” intelligence

- Battery power for use in harsh environments

- Accuracy +/-0,5% of reading from 20-100% of full scale

- Limit indication for up to 8 user defined target values

- Analog input

- Torque verification of all kinds of equipment

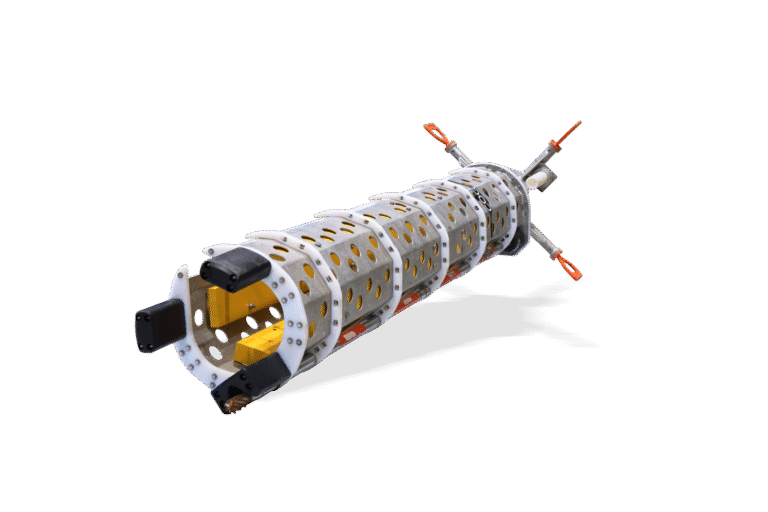

The Class 1-4 Test Jig is a Norbar designed torque verification unit.

This unit is used to give pre-dive surface confirmation of the torque tool calibration. It consists of a standard ISO class 1-4 torque reaction bucket with study base and built-in torque sensor.

The Test Jig Transducer system is delivered as a complete kit. (Instrument / Load cell + Test Jig)

The verification unit are calibrated once a year. The accuracy is class one. (+/-0,5% of reading from 20 to 100% of full scale)

Track record

Reservoir basket with integrated hose reel for barrier-testing a multiphase flow meter

A North Sea operator who had previously completed a similar operation with Envirent in 2022, came back for a reliable pumping solution to flush and barrier‑test a multiphase flow meter. Envirent...

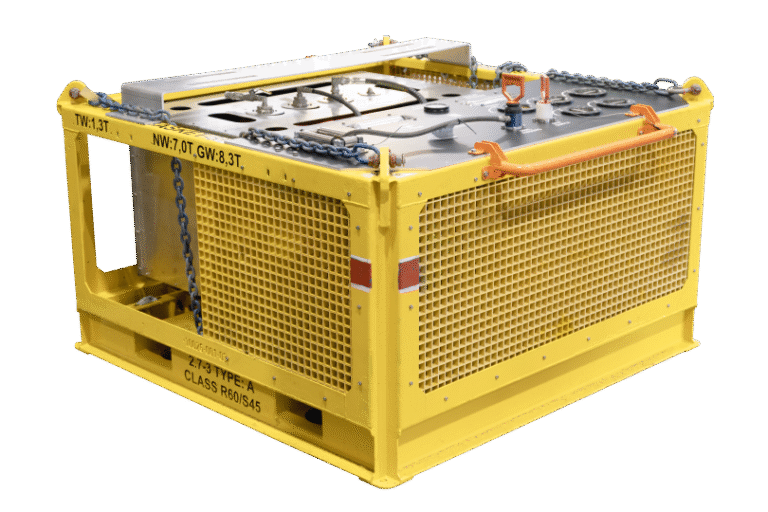

Read MoreIntegrated grease pump basket for subsea maintenance (IMR)

A subsea contractor needed to inject grease into rotating components during an IMR operation in the North Sea and returned to Envirent after a positive experience on a previous project. Envirent...

Read More