The Dirty Work Pack isolates the oil flow and prevents contamination of the main hydraulic circuit and can be tailored to customer requirements with different pressure and flow setups. A smaller fluid reservoir was selected because the job did not require a full 1 100 L tank.

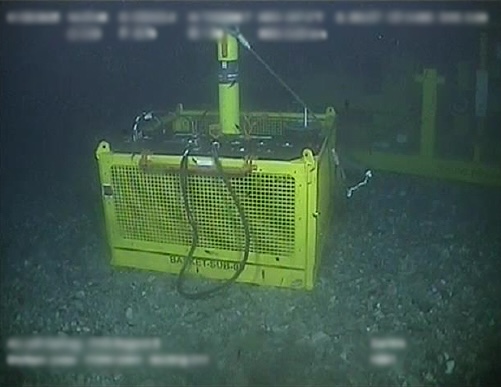

The basket was built as an evolution of a previous delivery for the same client (2021). During the factory acceptance test with the client, it became clear that extra lines were needed: one high‑pressure line for pressure testing and a low‑pressure line for flushing. These were integrated on the spot and verified, demonstrating Envirent’s agile process. Afterward, the team joined the vessel to run a familiarisation session with the ROV crew. The operation lasted from mid‑August to mid‑September 2025.

Case summary

| Industry | Oil&Gas (IMR) – SSIV flushing and pressure testing. |

| Delivery | Center Pole Basket with Dirty Work Pack and 50 L compensator. Two separate lines for pressure testing (∼220 bar) and flushing. |

| Customisation | Reservoir size reduced from 1100 L to 50 L. New lines integrated after client feedback during FAT. Updated design for easier handling. Envirent team supported installation and ROV training. |

| Duration/scope | Project window 15 August to 15 September 2025. |

| Location | Norwegian continental shelf |